Products

Contact Now

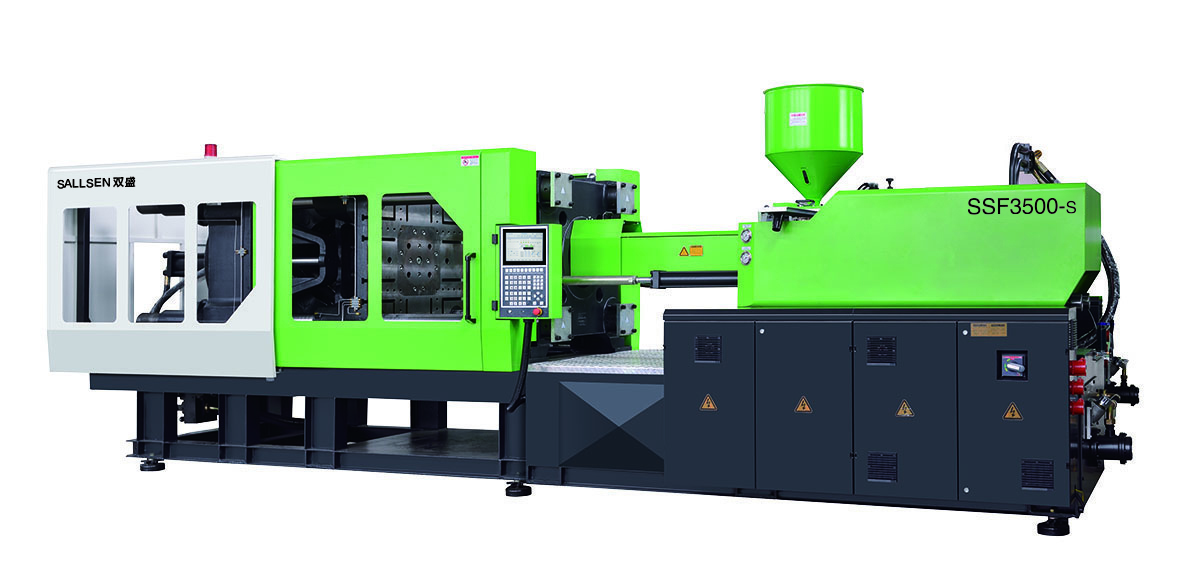

PET Injection Moulding Machine

Description

Reviews

Parameters

Application

For all kind of PET preform and PET plastic parts

Features

Apply PET specialized injection unit, screw L/D ratio 24:1, have excellent plasticizing capacity, suitable for various kinds of PET products;

Increase hydraulic ejection force, much suitable for deep cavity molding;

Two injection unit for selection.

Share your thoughts with us today!

Showing

6

of

0

reviews

Most recent

Top Reviews

Read more

Your rating

Your review *

Name *

Enter your Name

Email *

Enter your Email

Upload Image

Notice: Ensure your image is no larger than 200KB before uploading.

Submit

Contact Us Now

Enter your inquiry details, We will reply you in 24 hours.

Name can't be empty

E-mail can't be empty

Company can't be empty

Phone can't be empty

Phone

Products can't be empty

Products you want

Message can't be empty

Verification code error

Clear