Products

Contact Now

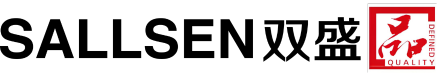

SH230 Hybrid Injection Molding Machine

Description

Reviews

SH230 Parameter

SH230 Features

Intelligent control module, increase machine perception.

It is equipped with standard temperature monitoring and real-time temperature display, which can accurately control the temperature of material feeding port.

Two sets of lubrication are provided as standard. Mold locking and electric injection are lubricated separately to ensure sufficient lubrication and reduce maintenance cost.

It is equipped with standard servo motor temperature monitoring, and the cooling fan is opened when servo motor reaches to a specific temperature, which can reduce noise and power consumption.

Standard hydraulic oil temperature monitoring, real-time temperature display, small hydraulic oil temperature rise, can achieve zero cooling water use.

The host computer can operate and monitor the auxiliary machine.

Optional with Hongsu Cloud monitoring system, the machine dynamic parameters and production efficiency integration will be real-time monitored by mobile phone.

Optional power meter monitoring system, real-time display of machine energy consumption, of which can calculate accurately the power cost of a single product.

Multiple modular injection device, convenient to expand all kinds of special engineering, reduce machine delivery time.

Electric injection device with precision linear guide can expand screw barrel of various lengths, equipped with standard precision and super durable screw, applicable to all kinds of engineering plastics.

Servo electric charging device, precise control of charging pressure and speed, can effectively ensure precision molding.

Double injection moving cylinder can stably control injection seat deformation.

Extra space reserved for electric box.

Mold clamping and injection movement at the same time, also for mold opening and charging and etc, it can solve all kinds of complex injection molding process.

Mold locking mechanism, strong rigidity of the overall machine frame, improve product stability.

Mold platen thicken, so relative deformation is small, the mold locating hole is small, can prolong the mold lifetime.

The second stage sliding foot joint design of the movable platen can ensure that the molvable platen copper sleeve is not worn.

The frame adopts through beam structure, with strong overall rigidity and small deformation.

Enlarged tie bar, clamping shaft and steel sleeve, reasonable lubrication design can ensure the effective service life of the machine.

The internal pressure mold closing oil loop design, with high precision of mold opening position.

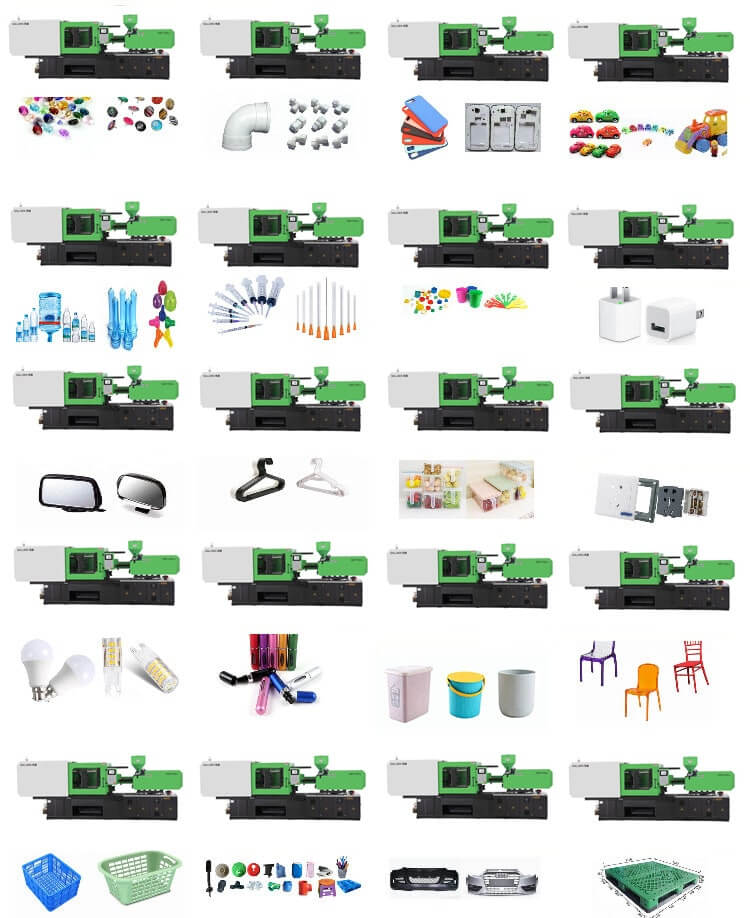

Application Range

If you have any query about our injection molding machine, just contact me at any time

Share your thoughts with us today!

Showing

6

of

0

reviews

Your rating

Your review *

Name *

Enter your Name

Email *

Enter your Email

Upload Image

Notice: Ensure your image is no larger than 200KB before uploading.

Submit

Contact Us Now

Enter your inquiry details, We will reply you in 24 hours.

Name can't be empty

E-mail can't be empty

Company can't be empty

Phone can't be empty

Phone

Products can't be empty

Products you want

Message can't be empty

Verification code error

Clear