Products

Contact Now

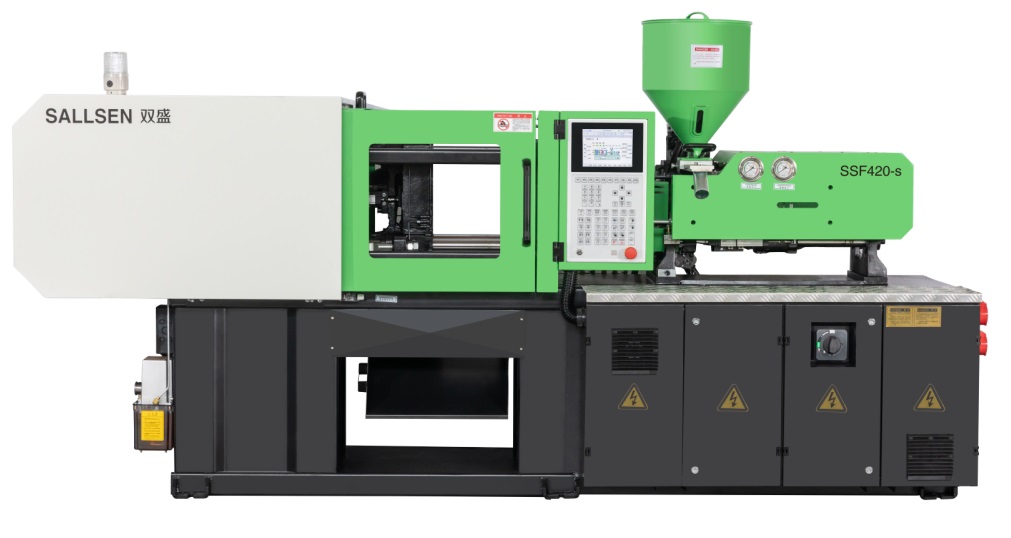

Small Servo Motor Injection Molding Machine(SSF420-S)

high quality

Description

Reviews

Shuangsheng is the top injection molding machine manufacturer in China. It has been providing manufacturing and customized injection molding machine services to customers worldwide. The clamping force of the injection molding machine provided by our servo system ranges from 32T to 480T.

Features of Our Servo Injection Molding Machine

- Double cylinder balanced injection system;

- Multi-stage pressure &speed injection;

- Back pressure adjustment device;

- Low-pressure mould protection;

- Single hydraulic core pulling and inserting;

- Multiple hydraulic ejector knock-out;

- Mechanical, electrical safety device;

- Auto lubrication system;

- Hydraulic pressure full proportional control;

- Computer control system;

- Molding data memory system;

- Automatic mould adjust function;

- Energy-saving with servo motor;

Parameters of 420kn Injection Plastic Machine As Below

Notes:

(1)Theoretical injection volume=screw diameter×screw stroke;

(2)Actual injection weight is 91% of the theoretical volume;

(3)All the data is PS values.

Remark: Above-mentioned technical parameters are all theoretical values in 50HZ operation state. The technical parameters are subject to change for technical improvement without notice.

(2)Actual injection weight is 91% of the theoretical volume;

(3)All the data is PS values.

Remark: Above-mentioned technical parameters are all theoretical values in 50HZ operation state. The technical parameters are subject to change for technical improvement without notice.

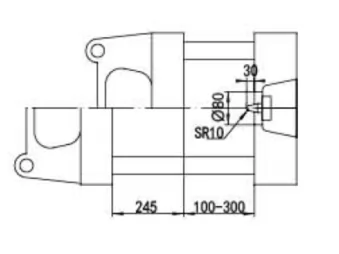

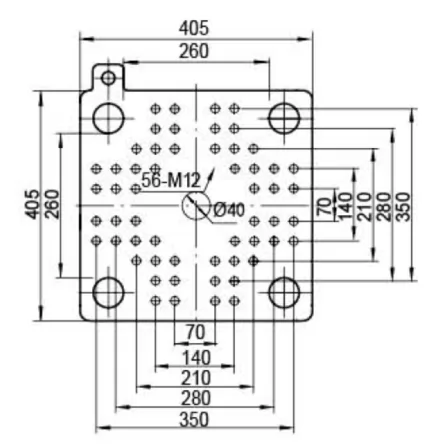

Mold Platen Drawing

Parts That Can Be Produced

Customized injection molding machine solutions for you now

Our smallest SSF420-S injection molding machines are applied to produce precision plastic parts like electronic small parts, plastic color chips and other small plastic parts, with its small size, fast cycle time, friendly operation screen, warmly welcomed by customers.

Advantages of servo motor

1.There is no extra energy consumption due to output volume changes according to load alteration. In the phase of holding pressure, servo motor lowers rotate speed and consumes a little of energies. In the phase of cooling, motor doesn’t work and consumes no energy. According to different products, servo energy saving injection molding machines will save 20%~80% energy and bring you prominent economic benefit.

2.High precision, high response: The pressure sensor and rotary encoder with high precision and high sensitivity achieve pressure, flow closed-loop control, allowing the repeat precision error to be less than 1%. It only takes 0.05 second to reach the largest output power.

3.Save the cooling water: No constant flow pump and speed set motor overflow heating. When the temperature of hydraulic oil is lower, the cooling water is greatly reduced.

4.Super energy saving: Compared with variable pump system, it can save 40% of the power. Compared with constant flow pump and fixed speed motor. It can save 60% of the power.(Different kinds of products have different energy saving effects.

5.Low noise: The noise is below 78db. Servo motor has almost no noise when no movement of machine.

Share your thoughts with us today!

Showing

6

of

0

reviews

Most recent

Top Reviews

Read more

Your rating

Your review *

Name *

Enter your Name

Email *

Enter your Email

Upload Image

Notice: Ensure your image is no larger than 200KB before uploading.

Submit

Contact Us Now

Enter your inquiry details, We will reply you in 24 hours.

Name can't be empty

E-mail can't be empty

Company can't be empty

Phone can't be empty

Phone

Products can't be empty

Products you want

Message can't be empty

Verification code error

Clear