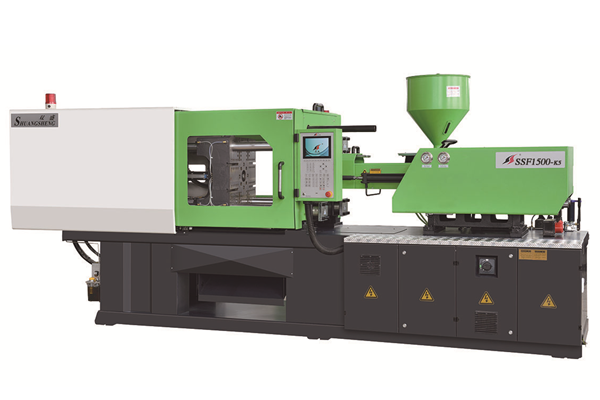

150T Fixed Pump Plastic Injection Machine(SSF1500-K5)

Description

Reviews

Main Features

- Automatic production, no secondary pollution, meets sanitary requirements

- Continuous production and high efficiency

- Controllable clamping force and good repeatability

Injection Molding Machine Parameters

| SSF1500 Parameters | |||||

| Items | Parameter | Unit | SSF1500 | ||

| Injection Unit | Screw diameter | mm | A | B | C |

| 38 | 42 | 45 | |||

| Screw L/D ratio | L/D | 23.7 | 21.4 | 20 | |

| Shot volume(theoretical) | Cm3 | 226 | 277 | 318 | |

| Injection weight(PS) | g | 206 | 252 | 289 | |

| Oz | 7.3 | 8.9 | 10.2 | ||

| Plasticizing Capacity | g/s | 16 | 22 | 28 | |

| Injection rate | g/s | 106 | 130 | 149 | |

| Injection pressure | Mpa | 223 | 183 | 159 | |

| Screw speed | rpm | 220 | |||

| Clamping unit | Clamp force | KN | 1500 | ||

| Open stroke | mm | 400 | |||

| Distance between tie bars (W*H) | mm | 430*430 | |||

| Max mould thickness | mm | 480 | |||

| Min mould thickness | mm | 160 | |||

| Ejector stroke | mm | 130 | |||

| Ejector force | KN | 45 | |||

| Ejector number | PC | 5 | |||

| Dia of mould location hole | mm | 125 | |||

| Others | Max pump pressure | Mpa | 16 | ||

| Pump motor power | KW | 13 | |||

| Heating power | KW | 10.3 | |||

| Machine dimension(L*W*H) | m | 4.5*1.35*1.9 | |||

| Machine weight | T | 4 | |||

| Oil tank capacity | L | 250 | |||

|

Notes:(1)Theoretical injection volume=screw diameter×screw stroke; (2)Actual injection weight is 91% of the theoretical volume; (3)All the data is PS values. Remark: Above-mentioned technical parameters are all theoretical values in 50HZ operation state. The technical parameters are subject to change for technical improvement without notice. |

|||||

Mold platen drawing

Application

Industry: electrical instruments, auto parts, medical parts, packaging, daily necessities, aviation tableware, children's toys, construction pipes, laboratories, etc.

Products: electrical enclosures, socket plates, gears, cages, droppers, bottle caps, preforms, cups, disposable plastic cutlery, hot wheels, PVC pipe fittings, color plates, splines, etc.

Contact Us

We have established cooperations with agents from Argentina, Colombia, Chile, Mexico, South Africa, Netherland, Denmark, Spain, Israel, Turkey, Russia, Pakistan, Iran to market and provide after-sales service to our small injection molding machines. We warmly welcome agents and customers from more countries to cooperate with us.

If you have any query about our injection molding machine, just contact me at any time

SSF1500-K5 injection molding machines, with energy saving features, applies to the injection molding process of various kinds of thermoplastics.

Advantages of servo motor

1. There is no extra energy consumption due to output volume changes according to load alteration. In the phase of holding pressure, servo motor lowers rotate speed and consumes a little of energies. In the phase of cooling, motor doesn’t work and consumes no energy. According to different products, servo energy saving injection molding machines will save 20%~80% energy and bring you prominent economic benefit.

2. High precision, high response: The pressure sensor and rotary encoder with high precision and high sensitivity achieve pressure, flow closed-loop control, allowing the repeat precision error to be less than 1%. It only takes 0.05 second to reach the largest output power.

3. Save the cooling water: No constant flow pump and speed set motor overflow heating. When the temperature of hydraulic oil is lower, the cooling water is greatly reduced.

4. Super energy saving: Compared with variable pump system, it can save 40% of the power. Compared with constant flow pump and fixed speed motor. It can save 60% of the power.(Different kinds of products have different energy saving effects.

5. Low noise: The noise is below 78db. Servo motor has almost no noise when no movement of machine.